Strong together: Welcome, robot colleague!

Artificial intelligence (AI) is rapidly becoming a part of our daily lives and work. From smart phones, watches, glasses, and household appliances to vehicles that control themselves with AI or chatbots such as ChatGPT , AI is poised to transform our world as radically as the the internet once did – experts around the world largely agree on this. Another area where AI will become increasingly important is logistics. The Otto Group recognized this early on and will soon be using AI-controlled robots from US start-up Covariant in its fulfilment centers as part of a strategic partnership. In November 2023, a first test station was set up at Hermes Fulfilment in Haldensleben, Saxony-Anhalt, to the delight and observation of the employees working there. After all, the new robot colleague will primarily reduce their workload, and at the same time enhance their job profiles in warehouse logistics. A visit on site.

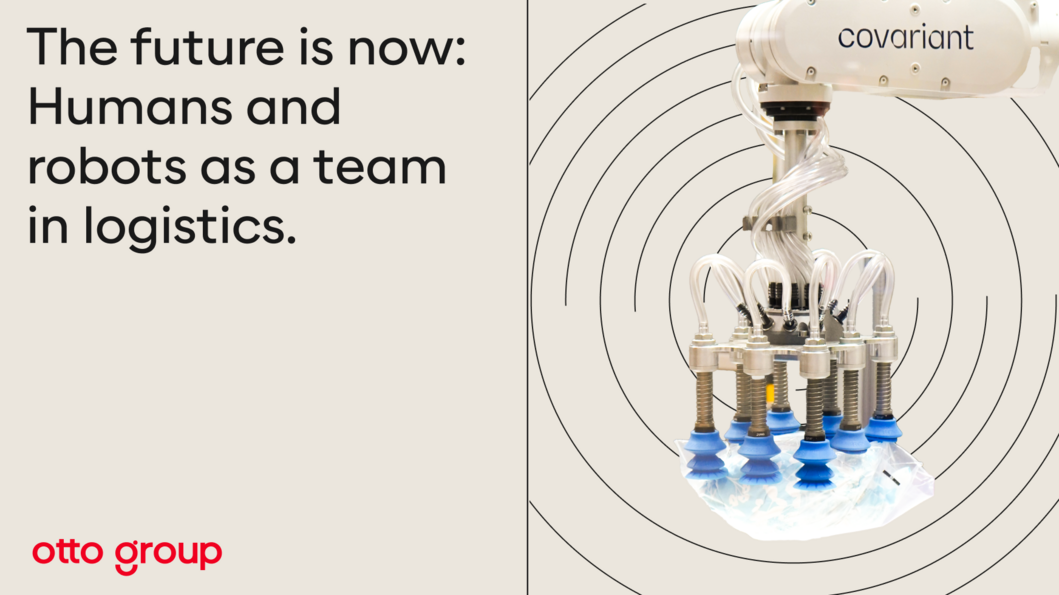

With a snappy, precise movement, the robot arm lowers itself into the purple tub filled with various goods. With the help of vacuum-operated suction cups, it grabs any product, lifts it up and gently drops it onto the conveyor belt next to it. The product is then quickly transported to the next station, where it is automatically placed in a shipping bag and labeled for shipment. The robot arm from Covariant lifts products out of the tub again and again without getting tired. Its challenge: the huge variety of shapes, colors and quantities of goods to be processed, which previously required human hand-eye coordination, such as so-called "limp" textiles. This is now possible with the help of AI in the so-called "Covariant Brain". Thanks to the unit with six cameras, the robot learns the different haptic properties of the various products and stores them in its electronic memory. For the next time and for all other robots in the fleet – across all logistics centers!

A few meters away is Birka Kreibich, who has been working in Hermes Fulfilment's individual shipping department at the Haldensleben logistics site in Saxony-Anhalt for 13 years. So far, she is doing a similar job to the robotics station: she takes an item out of a purple tub, checks the corresponding invoice, and then packs the item in a shipping bag or box to make it ready for dispatch. Again and again. From time to time, she glances curiously over at her new, futuristic colleague and is already looking forward to him taking over this repetitive work in the not-too-distant future. She and her colleagues were involved in the planning for the integration of robots into their working environment in advance and were able to contribute their ideas on how and where the robots could be most effective in the future. "Our work is physically demanding. With the support of the robots, it will be more varied and ergonomically better for us," she is convinced. Birka is not worried that the robots might take her work away completely. She knows that her new AI colleagues will give her the opportunity to concentrate on more varied and complex tasks that still require people – for example, guiding and controlling the robots and monitoring the work performed.

More than one hundred AI robotics stations will follow

But it's not there yet. The Covariant robot is part of a pilot test station that was put into operation at Hermes Fulfilment's logistics site in November 2023 in Haldensleben and is now being put through its paces. It is still the only one there. However, more than one hundred other AI robotics stations will follow if it passes all the tests. In August 2023, the Otto Group announced a strategic partnership with the Californian start-up Covariant, which insiders see as the world's leading provider of AI robotics. Covariant develops robots that use AI to make autonomous decisions and handle goods in a wide variety of shapes. A revolution in the world of logistics. Against the backdrop of these groundbreaking technological developments, logistics processes can be completely rethought and reorganized in the future: from the flow of goods to distribution and packaging to the movement of goods.

The new robot is also exciting for Marius Schneider, an operations technician in the dispatch area. He looks after the various technical systems at the Haldensleben logistics site and will therefore also be responsible for it in the future. "My new tasks will also include programming and maintaining the Covariant robotic stations as well as rectifying any faults that occur," he explains. Like his colleague Birka, Marius is convinced that the Covariant robots will make work easier for him and his colleagues in the future and ensure that the ordered goods reach customers even faster. At the same time, this and all other logistics innovations will expand his area of responsibility and create new, diverse challenges that he is happy to take on.

Support through internal training

In the future, Marius will receive support in dealing with the new technologies through various internal training measures as part of Techucation@Logistik . This program offers various learning modules to train employees in digitalization at all Hermes Fulfilment logistics locations. "This has reduced any reservations that people may have had about using the new technology at the beginning," he says. He therefore feels well equipped for the future and what lies ahead.

The use of AI-controlled robots is ushering in a new era, not just for experienced warehouse logistics employees. The range of tasks in logistics is also expanding significantly for the next generation, who are naturally closer to digitalization topics, such as 18-year-old Jonas Behrend, an apprentice industrial mechanic – and making the job profile even more attractive. A key factor in the battle for committed specialists and junior staff and a real benefit for Jonas in his day-to-day work.

I think it's very good that robots are now being used here. It makes work easier for my colleagues.

The project teams from the Logistics Consulting and Planning department at Hermes Fulfilment are responsible for the design, planning and implementation of the extensive tests at the new robot station in Haldensleben. The test phase is divided into three main sections, says project manager Björn Dörlemann: "First we test the technical performance during operation, then we start extensive tests with selected test articles, followed by real customer orders." However, it will be almost a year before the robot arms can be integrated into the existing system landscape.

Operations start in 2025

Jie "Betty" Hou, Senior Manager Supply Chain Management at the Otto Group, is managing the pioneering innovation projects from the Otto Group side. She has already the further roll-out next year in mind. The first robot arms are due to start regular operations at other Hermes Fulfilment locations as early as 2025. However, she is already very satisfied with the initial results delivered by the pilot station: "We can already see the future we are heading for here. As the Otto Group, we want to meet this future with courage and curiosity."

The colleagues at the Haldensleben site are happy to follow this path taken by the Otto Group and are looking forward to working with their robot colleagues in the future. Birka: "I think it will be exciting!"