Boston Dynamics was founded in 1992 as a spin-off of the Massachusetts Institutes of Technology (MIT).

Logistics of the future - How humans and robots work hand in hand

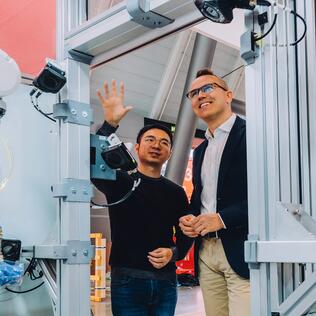

The Otto Group is entering into a strategic agreement with Boston Dynamics, the world's leading robotics developer. Logistics will change significantly as a result – especially to the benefit of employees.

One would think that sea freight containers, which are used to handle the majority of daily goods traffic, would be easy to unload by machine. After all, they are spacious and rectangular. But that's not the case. "True, you're dealing with cubic elements, which would actually make automated unloading easier. But then a lot of imponderables just come into play," explains Raphael Adrian Maier, Group Vice President Supply Chain Management at the Otto Group. "On the one hand, you can't determine in what kind of container the goods will be delivered from Shenzhen, for example. Then, the containers might be dented a bit. Or the goods have slipped. Also, sometimes the truck cannot be parked in such a way that machines can be used. In short, you have to deal with unforeseen situations that previously made automated unloading impossible."

For this reason, sea freight containers are still mainly unloaded by people today. Only they have been able to react flexibly to the varying conditions of the container and the goods. However, this work is laborious and physically demanding. If the containers are standing in the sun, it is often over 50 degrees inside. In winter, it is freezing cold. Loading the packages is strenuous and requires full concentration, so optimum workplace ergonomics are not a given. It is therefore not surprising that the shortage of skilled workers is particularly drastic at this crucial logistics interface.

Wanted: Autonomously acting robots

"Hence, we were looking for solutions with which we could work on this challenge and thus sustainably advance innovation in logistics," explains Maier. And so, the Otto Group came across the US company Boston Dynamics – the world's leading robotics developer. With its StretchTM product, Boston Dynamics offers a robot that has been specially designed to work in the demanding environment of containers. Stretch can handle a wide variety of boxes and adapts to changing conditions as it autonomously unloads a shipping container. Other machines have not been able to work here so far.

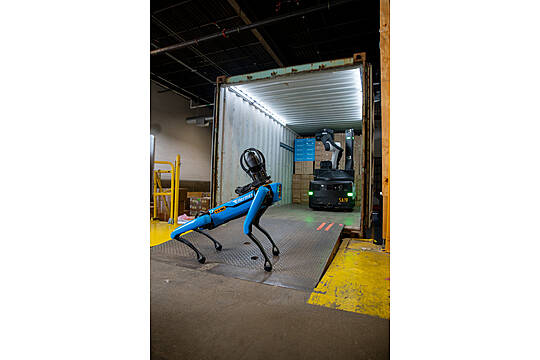

The Stretch robot – a movable base with a robotic arm – can move freely in space via a differentiated camera and sensor system, recognize objects and "manipulate" them, as it is called in robotics – in other words, move them. It does this via electric motors and dozens of small suction cups with a vacuum system that grips the boxes. Stretch also actively controls the electrically extendable conveyor belt on which the goods are placed and transported to the truck.

A classic win-win situation

The robot has the potential to do no less than revolutionize logistics – and in this way make it less dependent on the shortage of skilled workers. Stretch will begin unloading containers at ten sortable goods facilities next year, with the goal of having all more than 20 sites operational by the end of 2025. "We are in the midst of a tremendous transformation process and are constantly looking for new solutions that will enable us to make our business even more effective and satisfy customers even faster and better," says Group Service Director Kay Schiebur. "In Boston Dynamics, we have found the ideal partner: the biggest big player in the robotics industry. Together, we will redefine the field of logistics."

Boston Dynamics also expects a lot from the collaboration. "As one of Europe’s most innovative and forward-thinking companies, the Otto Group is a great fit for our technology," says Robert Playter, CEO of Boston Dynamics. "This agreement represents a strategic collaboration that will hopefully benefit both our companies for years to come, and we look forward to seeing the value our mobile robots can provide when combined with Otto Group’s deep expertise in logistics and fulfillment."

Regular checks in highly complex plants

In addition to Stretch, a second robot from Boston Dynamics will also be deployed at the Otto Group. Probably the company’s best-known product so far, Spot® is a four-legged "robot dog."

“Spot is a quadruped robot that was designed to go almost anywhere a person can,” explains Merry Frayne, Spot Product Manager at Boston Dynamics. “The robot has what we like to call ‘athletic intelligence’ built into it, which allows Spot to do things like dynamically maintain its balance, avoid obstacles, climb stairs, and traverse over many different kinds of challenging terrain.”

At the Otto Group, a special mission awaits the future Spot fleet: equipped with thermal cameras and noise detectors, they will complete tours of the highly complex facilities at Otto Group fulfillment sites. "Predictive maintenance" is the name of this approach, designed to detect potential damage before a facility fails. "In fully automated logistics plants, it is crucial that even difficult-to-reach locations are checked regularly – for leaks or changed noises, for example," explains Raphael Adrian Maier. "Until now, expensive monitoring equipment had to be installed for this at every critical point. The Spot remedies exactly this, it is mobile and brings the equipment to where it is needed."

This example also shows that people will not be superfluous in the future. On the contrary. In the case of predictive maintenance with Spot: The robot can indeed enter corners, corridors and tubes that are inaccessible to humans – but, of course, it must be controlled by a skilled worker to do so. "The robots cannot be left alone," says Maier. "They take on difficult jobs, but they have to be closely guided." This instruction can happen remotely in some cases – in individual cases even from the home office, he adds. Maier is certain that this will make a job in logistics even more attractive. He believes that robotics will also revolutionize the HR sector in the future: "Roughly speaking, mental work will replace physical work. Employees will become managers of robots."

Quick Facts Boston Dynamics

Many of Boston Dynamics' autonomously moving robots are designed for use in hazardous areas that would be too dangerous for humans.

In addition to Stretch, Boston Dynamics' best-known robot is a quadruped called Spot.