Digital Product Development: How Innovation Is Shaping a New Profession

Customers can buy nearly 30,000 garments and accessories in Bonprix’s online shop. What they do not see when they look at the products, however, is that ten percent of the range has been digitally created using a 3D avatar, without any physical patterns or a sewing machine. Is this the future of fashion development? The digital development of products has several benefits: it cuts the time to market in half, ensures a consistently high quality of the products and saves resources. New job profiles are also created.

Skills that we outsourced 20 years ago are now being brought back to the company so we can develop the styles ourselves.

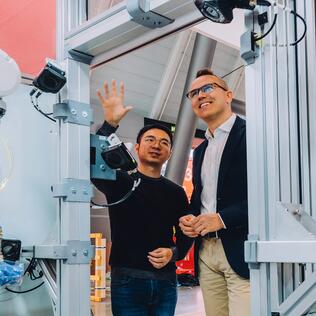

Bonprix believes in the digital future of fashion design: the company plans on digitalizing the entire product development process by the end of 2025, provided this is technically possible. Technical product developers (TPDs)—a new profession that has emerged going from from traditional production to digital workflows—will play a key role in this. Instead of acquiring the skills externally, Bonprix is focusing on further developing its own workforce. Interested employees can participate in a training program specially developed to give them the necessary skills, ranging from pattern development and grading (i.e., preparing a style in all sizes) to using 2D or 3D software and communicating with suppliers.

When Solveigh started working at Bonprix just under two years ago, she had already acquired extensive experience and skills. She hadd spent 10+ years working as a freelance patternmaker and 3D artist for reputable brands, meaning she knew the ins and outs of both worlds—conventional manufacturing using physical patterns and the digital process using so-called “digital twins”, the virtual representation of garments.

From the Briefing to the Digital Pattern

Whether digital or physical, every new garment respectively every new style begins with a briefing from Product Management, Bonprix’s creative department and birthplace of all new collections. In the traditional process, the team would meet in person to discuss the model. With international teams now working on the creation of a new product, this method is becoming increasingly less feasible. The new digital process, however, offers a collaboration tool that includes images and a list of attributes used to brief technical product developers about whether a top should have a V-neck or round neck, long or short sleeves, and what the fabric of choice is.

As a technical product developer (TPD), Solveigh picks out one of the styles planned and then has to decide which standard cut provides the best foundation for developing a pattern in line with the fit concept outlined in the briefing. Traditionally, patternmaking as well as pattern grading in all sizes were carried out by the textile manufacturer – now, Bonprix is bringing back these skills to the company.

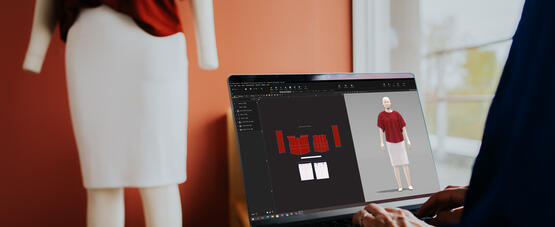

An example: For a rust-colored top with flared sleeves, Solveigh went with the standard cut for a boxy shirt—a baggy and wide-cut tee—with a bust measurement of 52 cm. In a 2D software, she then takes this basic cut to develop all the necessary pattern pieces. These pieces are transferred to a 3D software where they are sewn together virtually. In the traditional process, this work was carried out on a physical sample, but today it is all done digitally. Side seams are sewn, shoulder seams closed, and darts created until the style is finally ready for the simulation and fitting on a virtual avatar.

This avatar is the digital twin of the dressmaker’s mannequin used by Solveigh and her colleagues for the physical pattern fitting during the traditional development process. Since the process has not been switched over entirely yet, these mannequins can still be found standing next to the measuring tables in Bonprix’s Quality Development department with the same proportions and measurements.

3D Fitting on a Virtual Avatar

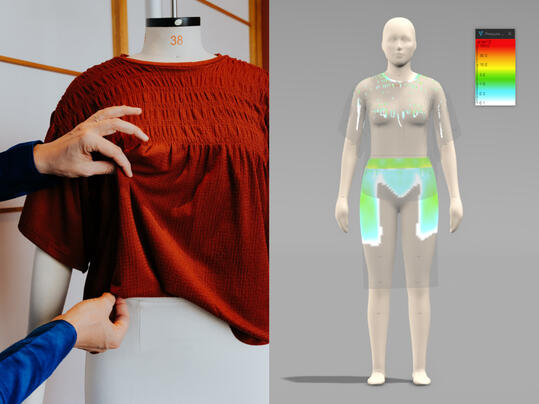

Once the garment is sitting just right on the avatar, Solveigh selects the digitalized fabric. In the case of the rust-colored top, it is crêpe fabric. This, however, only describes the surface texture of the fabric, which is not enough information for a proper fitting. That is why Bonprix’s Fabric team analyzes the physical features of all fabrics by stretching the original fabric in a fabric analyzer to determine the weight, resilience, and stretchability. All important pieces of information required for evaluating the fit on the avatar. Fabric behaves differently depending on the physical properties.

The TPDs are provided with several fitting tools in the 3D software. Solveigh can use the pressure map, for instance, to see how much the fabric lies on the body. If thestraps are too short and cut into the skin, for example, there would be a red- or orange-colored area in the pressure map, and Solveigh would know to extend the straps. The tension map tells you where and how much the fabric is stretched on the body. This allows Solveigh to see how tight or loose the style is. “The avatar isn’t able to talk to us—so the tools are very important in order to be able to really assess the fit,” she says.

From the Virtual Avatar to Physical Manufacturing in All Sizes

Once the final style has been approved for manufacturing, further work can be carried out in parallel processes. For one, the developed style can move on to the “awarding” phase, where a supplier who can manufacture the style in all the desired sizes is selected. The tangible benefits of digital development for sustainability can really be seen here: the traditional process sometimes required around four to eight physical samples before manufacturing could start—digital product development, however, saves these resources and emissions.

Meanwhile, Solveigh looks after the “grading”: she uses tension and pressure maps to verify if the style’s fit can be made uniformly for all sizes. This step is particularly relevant for Bonprix as the fit is very important to the company. While other brands use the “digital twin” above all as content for their online shop and social media, the company decided to look at the process holistically from the very beginning. “We want to take advantage of all the benefits offered by digital product development—we want to offer our customers a consistent fit and become more sustainable at the same time. And we are daring enough to do fittings in 3D,” says Solveigh.

Once all quality development processes have been completed and the right supplier has been found, it is time for the style to be manufactured. Here,the digital process differs from the traditional process again: the order is placed directly by the TPDs, who put together a package of measurement charts, renderings, patterns, and grading sizes for the manufacturers, and who remain in direct contact with the supplier. This expedites the process and illustrates how challenging the new role of technical product developer (TPD) is: on the one hand, colleagues must have in-depth expertise when it comes to measuring concepts, fit classes, fabric properties, and their finishing, as well as knowledge about suppliers and production processes. On the other hand, creativity, consulting expertise, a feel for European fashion, and the technical skills required for using 2D and above all 3D technologies also make up part of the TPD profile.

Digital Product Development—Quick, Flexible, Consistent, and Sustainable

Of course, new processes and job profiles are not an end in themselves; they were introduced because they offer a variety of benefits. For Bonprix, digital product development is not just about shortening the time to market and increasing supply chain flexibility. It is also about improving product quality and offering customers consistent and contemporary fits. The digital process also makes it possible to respond faster to customer wishes, for example if specific reasons for returning a style begin piling up or reviews show that the fit is suboptimal. At the same time, the new development process is also more sustainable, as resources are conserved and shipments reduced. Digital product development—definitely the future of the fashion evolution at Bonprix.

- • Consistent fit: Consistently high product quality guaranteed

• Efficiency: Speed in the process chain

• Flexibility: Ability to quickly respond to trends

• Sustainability: Reduction in physical patterns and production and transport emissions